When maintaining a profiled metal roof, there are several problems that can require attention but one of the most common is cut edge corrosion.

With over 40 years of coating experience behind us at Tor, we’re here to help explain what cut edge corrosion is, how it can affect you and what you can do to deal with it.

What is cut edge corrosion?

Cut edge corrosion occurs most commonly on steel cored coil coated materials used in vertical and pitched roofing applications. Plastisol is the most common but PVF2 and other coil coated materials can be affected. The manufacturing process coats both sides of the galavanised steel sheet with a protective system. A thin liner enamel on the inside and a primer plus 200 microns of plastisol on the outer surface. The product is rolled into large coils before being sent for cutting and profiling.

As the profiled coated sheets are cut to the required size the ‘cut edges’ have no protective coating in place. Over time, exposure to weathering and the elements leads to localised corrosion on the sheet edges – hence ‘cut edge corrosion.’

What problems can it cause?

Cut edge corrosion is initially unsightly but left untreated, can cause issues like water ingress and severe weakening of the sheet edges which will require a full removal and replacement, bringing unnecessary expense.

How can I prevent cut edge corrosion?

Prevention would include treatment of the cut edges with a protective coating system when the building is being built but this rarely happens in practice. Therefore the development of cut edge corrosion treatments has become a popular way of extending the life of coil coated cladding materials.

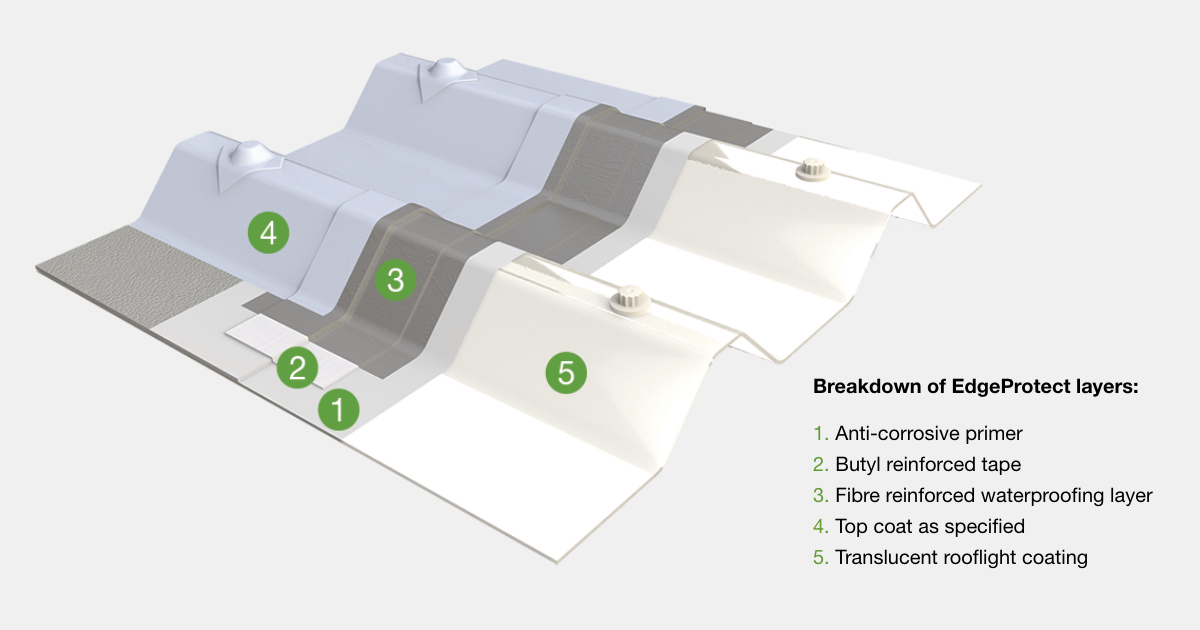

At Tor we have developed a simple approach to dealing with cut edge corrosion. It involves removing the corrosion, applying a high performance anti-corrosion primer. We then apply a reinforced butyl tape across the sheet end and then immediately overcoat with a fibre-reinforced waterproof coating. If required, colour matched topcoats can be included to provide life expectancy from 10 -25 years. The systems are marketed under the Unicover brand name.

What is Unicover?

When Tor coatings was founded in 1975, we set out with the intention of producing only high-performance, durable products that would make us the lead in the field of coating systems. We knew how prevalent cut edge corrosion was in construction, so we pioneered a zinc-based formula that would also repel water, and used it to create our Unicover Cladding systems.

The Unicover systems can offer many options from simple edge treatment alone and upto and including full roof waterproofing and redecoration. The systems are very cost effective and simple to use for contractors.

Warranties

The Unicover systems are covered by our single point warranty and on top of this we provide a personalised insurance backed policy guarantee free of charge* when the installation is carried out by one of our Tor Partner contractors.

To find out more about how Tor can help you with a project or specification, contact us here. You can also book one of our accredited online CPD courses on Waterproofing of Flat and Pitched roofs.

*Subject to underwriters terms and conditions