Roofing

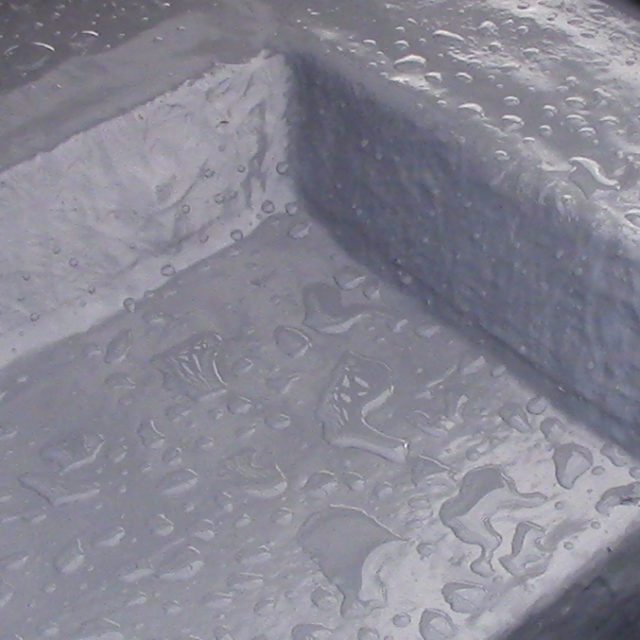

Our high quality roofing systems work to repair damage, prevent leaks, increase building efficiency, reduce energy demand and dramatically improve the performance of the roof to minimise costs and deliver long-lasting protection for years to come.